Chambersburg: A Closer Cut

Our Chambersburg division has been part of Olympic Steel for more than 25 years, shaping the heavy-duty parts that help lifts rise and booms extend. This closer look shares how the division works today, what’s changing and how they’re preparing for Chambersburg 2.0 and beyond.

Tucked into south-central Pennsylvania, our Chambersburg division has been part of Olympic Steel for more than 25 years. It also holds a special place in our history as the Company’s first fabrication-focused facility, opening in the late 1990s and setting the stage for the broader fabrication strategy we know today. Its location, just minutes from some of the country’s major equipment manufacturers, positions the division as a key contributor to the steel parts that keep material-handling and construction equipment moving.

Much of the work happening in Chambersburg is embedded in machines we see every day. JLG, the division’s largest customer, builds telehandlers and aerial lifts, the equipment that moves pallet loads to rooftops or raises workers into hard-to-reach places. Many of the steel pieces behind those machines—the big components that do the heavy lifting—come from the Chambersburg shop floor. In fact, about 65% of the division’s work supports JLG, while about 20% of the work involves traditional plate distribution.

The Chambersburg division spans about 26 acres and two buildings, with each playing a distinct role. The 1599 building, which began operations in 1999 and underwent an expansion in 2006, is where everything begins. It focuses on fabrication processes like burning and cutting, often laying the foundation for the work that follows across the division. A short walk away, the 1530 building, acquired by Olympic Steel in 2009, supports the next phase of production. It houses the division’s machining centers, including a new Doosan Bridgemill added last year, where parts are milled, drilled, welded and shaped with precision.

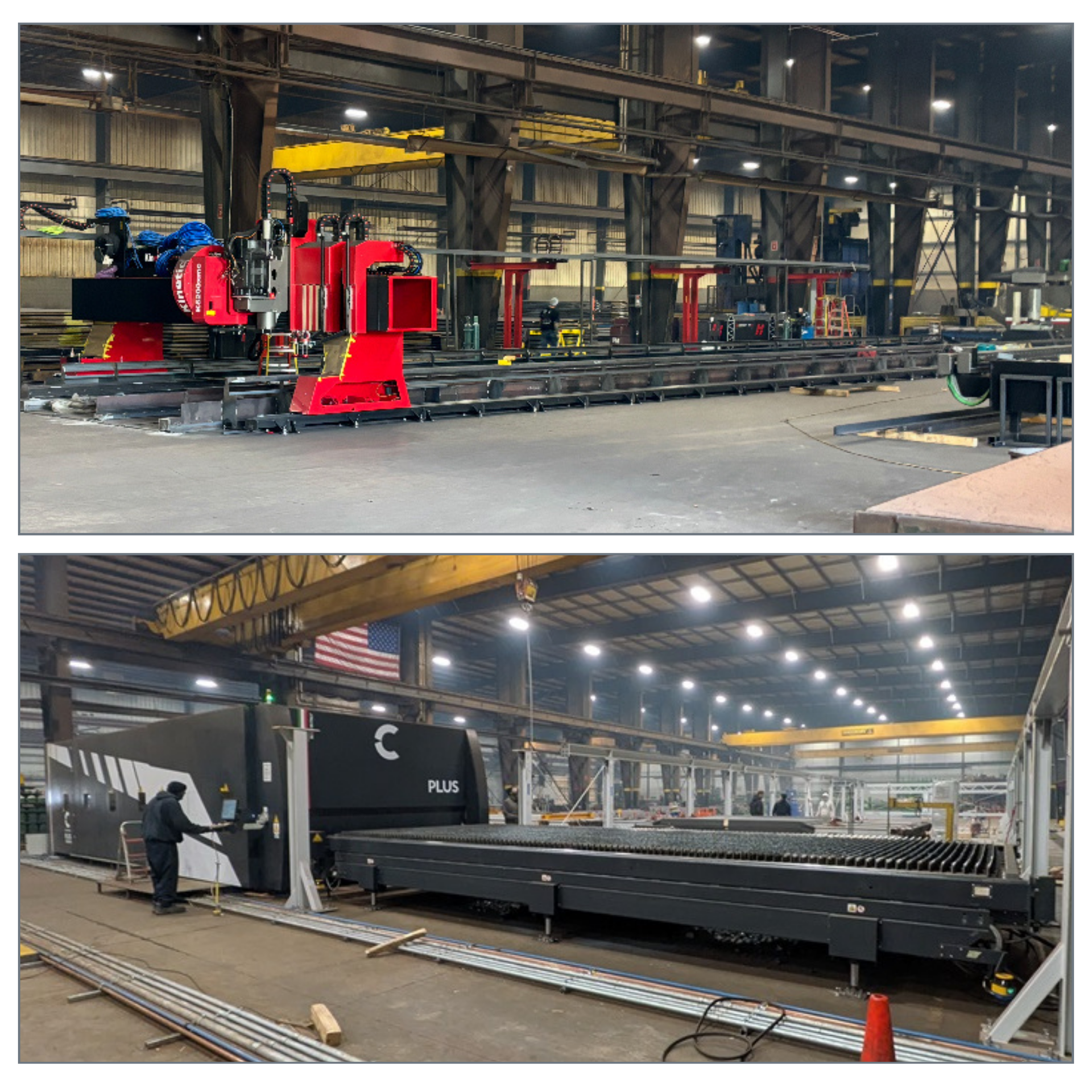

Today, the 1599 building is where the division’s latest transformation is taking place. Known as Chambersburg 2.0, the project brings in a 260-foot, fully automated parts manufacturing system to replace older equipment and more manual processes. At the center of the line are two 30kW fiber lasers: the most powerful available today—as well as a smart material-handling crane and a high-definition plasma cutting table. The upgrade also includes a new Kinetic Plasma multi-process system with cutting and machining capabilities, which is already live on the production floor. The 2.0 systems take on much of the physical work that used to be done by hand, meaning operators and handlers will no longer need to climb onto tables or manually reposition heavy plate. The result is a state-of-the-art facility with safer, cleaner and more efficient workspaces, plus added capacity to better support current customers and open the door to new opportunities. All systems are expected to be fully up and running in the first quarter of 2026.

And they’re not stopping there. Once 2.0 is fully operational, attention will shift to “3.0”—updating the 1530 building so the machining side of the division can fully support the increased volume 2.0 will generate.

Meanwhile, the Chambersburg team continues to make an impact in their community as well. From supporting Make-A-Wish and Adopt-A-Family programs to partnering with the Chambersburg Business Alliance and joining local events, they take pride in staying involved and giving back in ways that strengthen their local community and reflect Olympic Steel’s Core Values.

Keep learning and growing with us! Visit Olympic Steel Academy for more on the work we do, including our products, processes, services, Family of Brands and more.