Get to Know Buford & Winder

Our Buford and Winder, Georgia divisions play distinct roles in Olympic Steel’s operations. Get to know a little more about the work happening at each location, who they support and the teams who make it all happen.

Located just miles apart about an hour outside of Atlanta in northeast Georgia, our Buford and Winder divisions couldn’t look more different once you step inside. While both support Olympic Steel’s operations in the Southeast, what happens inside each building reflects a different moment in the steel’s journey: preparation in Winder and transformation in Buford.

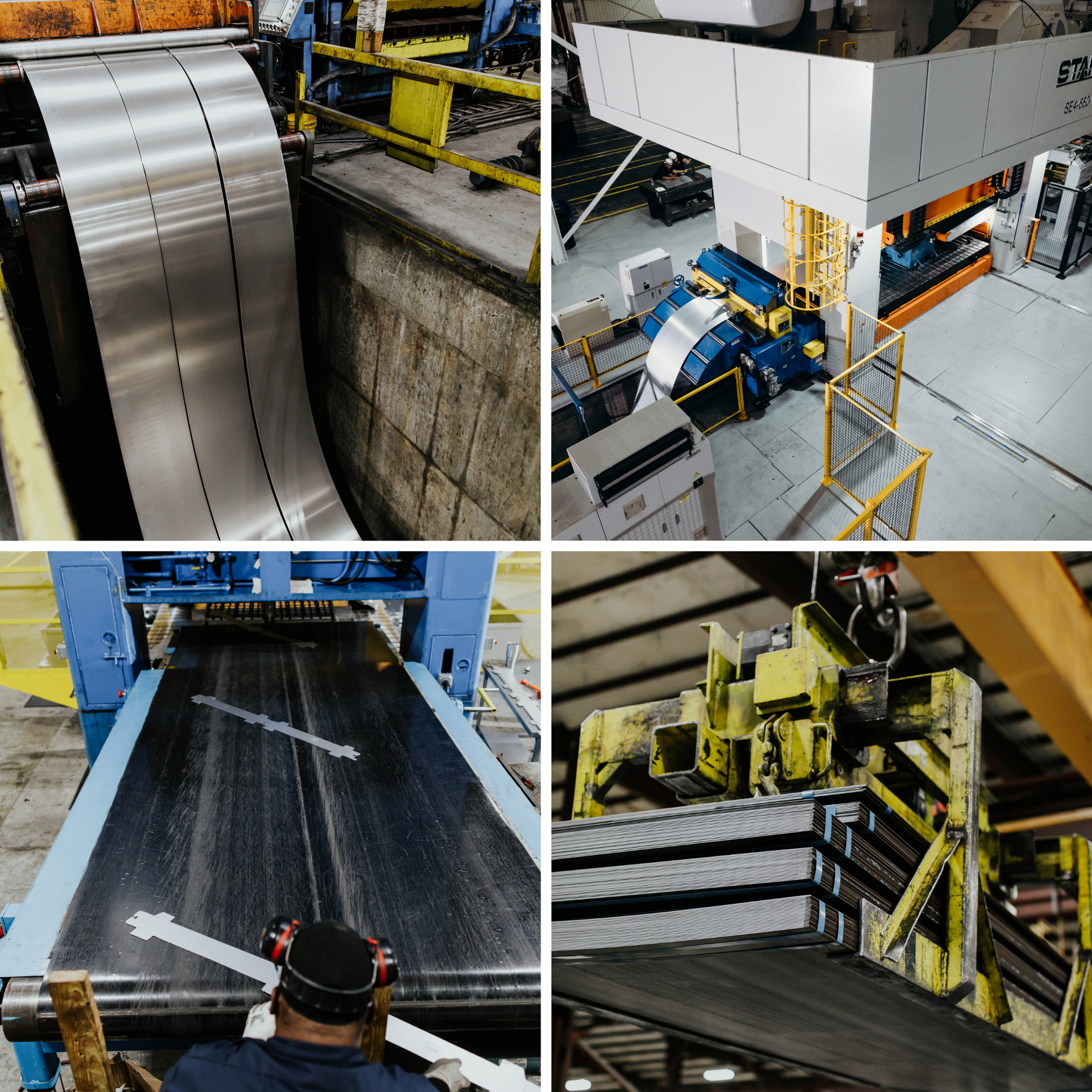

Winder, which began operations in 1997, was one of the Company’s first steps toward putting processing capabilities on the ground in the Southeast. Its focus is flat-rolled steel processing and distribution. Steel arrives primarily in coil form and moves through slitting and leveling before leaving the facility as sheet or plate.

When the job calls for it, Winder’s specialized coil-fed stamping presses handle blanking in-house, allowing the team to produce precise, repeatable blanks at volumes and consistency not typical of most metals service centers. Material processed at Winder supports a wide range of industries, including HVAC, automotive, defense, lighting and food service. Because of that reach, Winder-processed steel shows up in many familiar but often unseen places, from behind-the-scenes components inside gas stations to structural parts inside vehicles.

Where the steel goes next depends on the customer and the job. In some cases, Winder’s role ends there, with material moving directly into customers’ manufacturing processes. In other cases, the steel stays close and continues its journey through fabrication handled by Olympic Steel.

For a period of time, that fabrication work was handled alongside processing at Winder. As demand for value-added fabrication grew, so did the need for a space dedicated to the service, leading to the opening of the Buford facility in 2020.

Today, when Olympic Steel is responsible for that next stage, the material makes a short trip down the road to Buford, where the focus shifts from preparing steel to shaping it. Cutting, forming, machining, welding and finishing turn flat material into finished components for customers—primarily agricultural Original Equipment Manufacturers (OEMs). Those parts go on to become pieces of larger agricultural and construction equipment.

Behind the work at both locations are teams who take pride in living out our Core Values—doing things right, doing things consistently and doing things safely. You see it in long-standing customer relationships, in employees who have spent years—sometimes decades—learning the work, and in the way teams support one another on the floor to keep things running smoothly. That same sense of pride carries beyond the day-to-day work, through shared traditions, milestone celebrations and continued involvement in the community, especially supporting the Make-A-Wish Foundation each year.

Keep learning and growing with us! Learn more about the work we do through the Olympic Steel Academy.