Processing: Welding

Welding, a process used across many industries, joins metal materials using heat, pressure, or both, to produce a strong, permanent bond.

HISTORY

Olympic Steel began welding in our Chambersburg, PA division in the early 2010s. The addition of a welded frame and other components was a natural fit for a customer who makes industrial lifts that we were already cutting parts for. We have since added or increased welding processes to our facilities in Bartlett, IL, Buford, GA, Mt. Sterling, KY and our Action Stainless, Central Tube & Bar, EZ-Dumper, McCullough Industries, Metal-Fab and Shaw Stainless & Alloy subsidiaries. Our Chicago Tube & Iron (CTI) subsidiary was providing welding services prior to our acquisition in 2011.

THE PROCESS

Welding is a versatile fabrication process that joins materials, usually metals or thermoplastics, by applying heat, pressure, or a combination of both, producing a strong, permanent bond. Each welding process has unique advantages and is suited for specific applications.

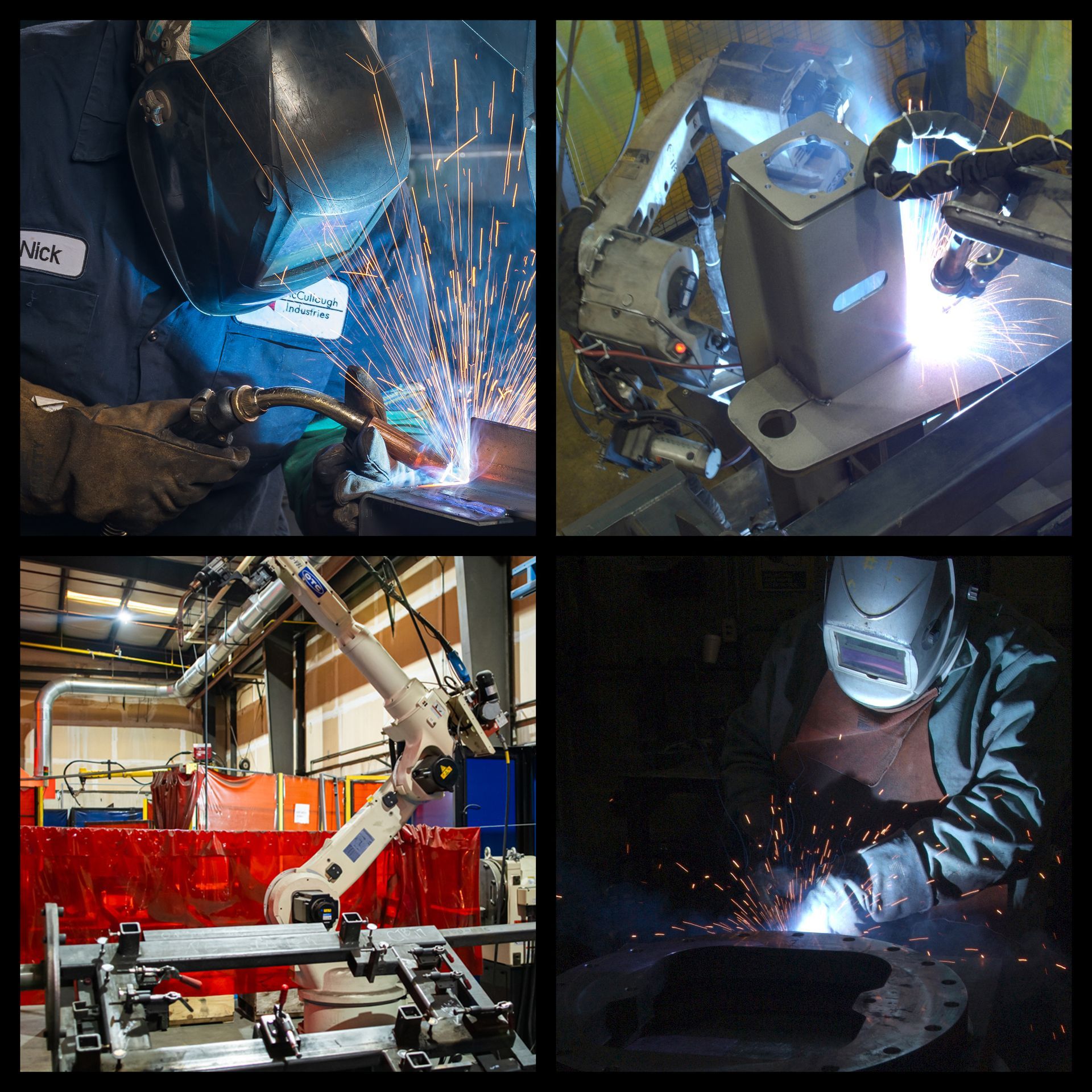

MANUAL WELDING

Manual MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding are types of common manual welding methods. The process used depends on the component and factors such as thickness, environment, and seam appearance. We offer manual welding in these divisions:

- Olympic Steel - Bartlett, IL

- Olympic Steel - Buford, GA

- Olympic Steel - Chambersburg, PA

- Olympic Steel - Mount Sterling, KY

- Action Stainless

- Central Tube & Bar

- Chicago Tube & Iron

- EZ-Dumper

- McCullough Industries

- Metal-Fab

- Shaw Stainless & Alloy

ROBOTIC WELDING

A robotic weld cell combines robotic arms, power sources, safety enclosures, and control systems with programming software to automate the welding process. We have robotic weld cells in these facilities:

- Olympic Steel - Buford, GA

- Olympic Steel - Chambersburg, PA

- Olympic Steel - Mount Sterling, KY

- Central Tube & Bar

- Chicago Tube & Iron

- Metal-Fab

- Shaw Stainless & Alloy

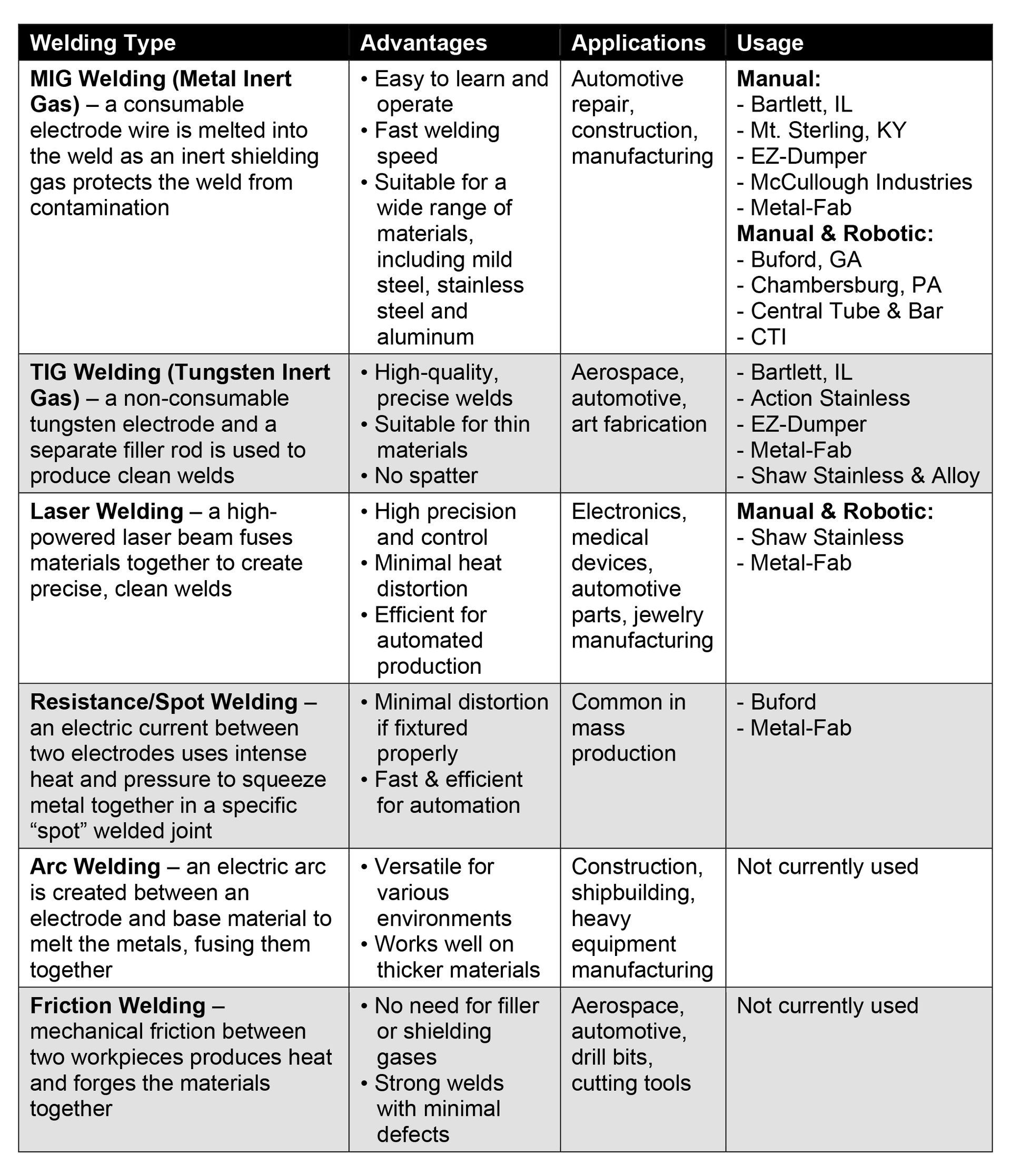

TYPES OF WELDING EXPLAINED

There are numerous types of welding processes, each with its own advantages, disadvantages and specific applications that consider various factors including the type and thickness of material, desired appearance, usage and the environment.

PRODUCTS

Welded items are all around us. You get into your vehicle, get your coffee at a drive-thru restaurant, merge onto the highway, cross a bridge on your way to the airport, and become part of the skyline on your approach to your destination. Each of those tasks were made possible with welded items. From consumer goods, like your lawn mower and HVAC system, to handrails on the stairs, metal desks, construction equipment and the sculptures in the park, welding builds the world around us and makes modern life possible.

OUTLOOK

Our manufacturing capabilities and processes enable us to support customers with additional services as their needs evolve. As we continue to strengthen our focus on value-added fabrication services, welding remains a fundamental part of Olympic Steel’s strategy for achieving safe, profitable, and sustainable growth.

Learn more about our processes, family of brands, business segments, divisions and subsidiaries at Olympic Steel Academy!